| Clausing 8520 Mill |  |

|

|

|

|

|

|

|

| Overview: Restoration and modification of a clausing 8520 Mill

|

|

|

Mill Parts (1/03/2006): Mill column |

|

Mill Parts (1/03/2006): Mill column |

|

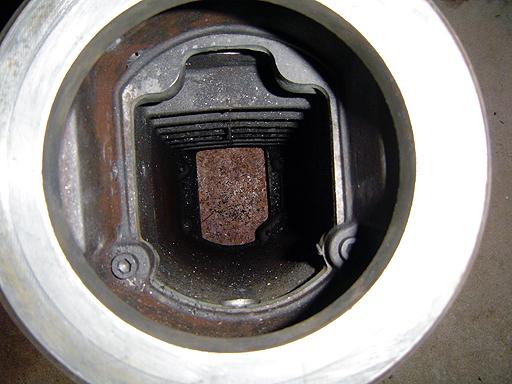

Mill Parts (1/03/2006): Mill column, interior |

|

Mill Parts (1/03/2006): |

|

Mill Parts (1/03/2006): |

|

Mill Parts (1/03/2006): Spindle |

|

Mill Parts (1/03/2006): Motor mount, and speed adjustment pulley. |

| Mill parts were stripped of paint and rust was buffed off of the cast iron. The iron was then sprayed with a rust inhibitor/remover and painted with an epoxy enamel. | |

|

Mill Restoration (1/03/2010): Repainted column |

|

Mill Restoration (1/03/2010): Repainted column |

|

Mill Restoration (1/03/2010): Repainted column |

|

Mill Restoration (1/03/2010): Table mounted and lead screw installed, lead screw threads are in good condition. |

|

Mill Restoration (1/03/2010): Mill re-assembled with spindle mounted |

|

Mill Restoration (1/03/2010): Mill re-assembled with spindle mounted |

|

Mill Restoration (1/03/2010): Motor and belts attached. Motor and starting capacitor are faulty and will have to be replaced. |

|

Mill Restoration (1/03/2010): Under the knee. |

|

Mill Restoration (1/03/2010): Under the knee. |

|

Mill Restoration (1/03/2010): Mill table. |

By attempting to reproduce any experiments or devices listed on this domain in part or in whole, you agree to hold me harmless against any lawsuit or liability. Copyright © 1998 - 2005 by Andrew Seltzman. All rights reserved. |

|

| Contact me at: admin@rtftechnologies.org | |