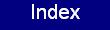

| 5 Axis Desktop CNC Hardware |  |

|

|

|

|

|

|

|

| A 5 axis desktop CNC for rapid prototyping, 3D milling, and circuit board fabrication. The 5-axis CNC mill will mainly be used to mill parts and circuit boards for the mark3 fusor.

|

|

General specifications:

|

|

Aerotech ATS100 stages (3/09/2010) Shown with z-axis encoder cover removed. Zero backlash high precision servo driven stage

|

|

LBK encoder (3/09/2010) 1000 line/rev quadrature encoder

|

|

Encoder wiring (7/31/2010) Cabling connects encoder to external connector.

|

|

Encoder wiring (7/31/2010) Encoder is connected to RJ-45 jack for connection to whale3 encoder input.

|

|

Aerotech ATS100 stage (3/09/2010) Precision linear ways and ball screw. |

|

Aerotech ATS100 stages (3/09/2010) Precision linear ways and ball screw. |

|

Helicoil thread repair kit (3/09/2010) Two of the M6 threads were stripped out on one of the stage mounting plates, these were repaired with a helicoil kit. |

|

Repaired thread (3/09/2010) Thread repaired with helicoil insert. |

|

Mounting base (3/20/2010) Two 18" rails made from 8020 aluminum extrusion are used to mount the stages. Triangular joining plates space out rubber anti-vibration feet fro greater stability. |

|

Mounting base attached (3/20/2010) Bolted onto base of mill. |

|

Mounting base (3/20/2010) Back of mill. Eventually a riser plate will be added hear above the servo motor and the z-axis will be moved back onto it. |

|

X and Y axis (4/02/2010) X and Y axis with adapter plate mounted on x axis stage

|

|

Standoffs (4/02/2010) Standoffs to mount z axis riser plate.

|

|

Riser plate (4/02/2010) Riser plate adapts 8020 base to metric bolt pattern for z axis

|

|

Riser plate (4/02/2010) Mounted on standoffs

|

|

Z axis (4/02/2010) Z axis mounts on riser plate

|

|

Tooling plate adapter (4/02/2010) Allows mounting of tooling plate with 10-32 bolts with 0.5" spacing onto to Aerotech stage which has M6x1.0 metric bolts on 75mm spacing.

|

|

Ball reducer (3/20/2010) Kamoseiko BRN23-15G ball reducer, will reduce output of a 1000DC servo motor driving the A-axis. NEMA23 mount, 15:1 ratio, zero backlash, 1/4" input shaft 3/8" output shaft. |

|

A-axis parts (3/28/2010) Ball reducer, adaptor bolt to adapt 3/8" shaft to 3/4-16 thread, and 4 jaw 2.5" chuck.

|

|

A-axis parts (3/28/2010) Adaptor bolt mounts on reducer shaft.

|

|

A-axis parts (3/28/2010) Chuck screws onto bolt. |

|

A-axis parts (4/02/2010) Aerotech 1017LT servo motor connects to reducer

|

|

A-axis motor (5/16/2010) Servo motor shaft for connecting encoder.

|

|

A-axis encoder (5/16/2010) 1000line/rev quadrature encoder with index pulse. |

|

A-axis encoder (5/16/2010) Mounted in a-axis motor.

|

|

A axis mounting bracket (5/16/2010) Right angle bracket to mount a-axis rotary stage onto the tooling plate.

|

|

A axis (5/16/2010) Right angle bracket to mount a-axis rotary stage onto the tooling plate.

|

|

Tooling plate (5/16/2010) 7075 aluminum tooling plate (4"x12"x0.5") will be mounted onto x-axis stage and hold the A-axis rotation stage. |

|

A axis mounted (5/16/2010) A axis mounted on tooling plate. |

|

A axis mounted (5/16/2010) A axis mounted on tooling plate.

|

|

Right angle reducer (3/20/2010) Right angle reducer to rotate spindle around the y axis. 30:1 ratio, worm drive, low backlash, 10mm output, 8mm input |

|

B axis mounting plate (6/25/2010) Mounting plate with motor screw slots to allow tensioning of drive belt. |

|

B axis pulley (6/25/2010) Hub turned down to fit stage. |

|

B axis motor mounted (6/25/2010) Motor with reducing pulley mounted on right angle drive platform. |

|

B axis motor mounted (6/25/2010) 3:1 reduction with pulleys. |

|

Lower B-axis stop (7/31/2010) Lower hard stop for b-axis.

|

|

Upper B-axis stop (7/31/2010) upper hard stop for b-axis.

|

|

B-axis stops mounted (7/31/2010) Stops mounted on b-axis stage.

|

|

Toolmakers vice (5/16/2010) Small 2" precision vice for holding stock used in 3 axis work. |

|

Digital indicator (5/23/2010) Digital indicator for measuring mill alignment.

|

|

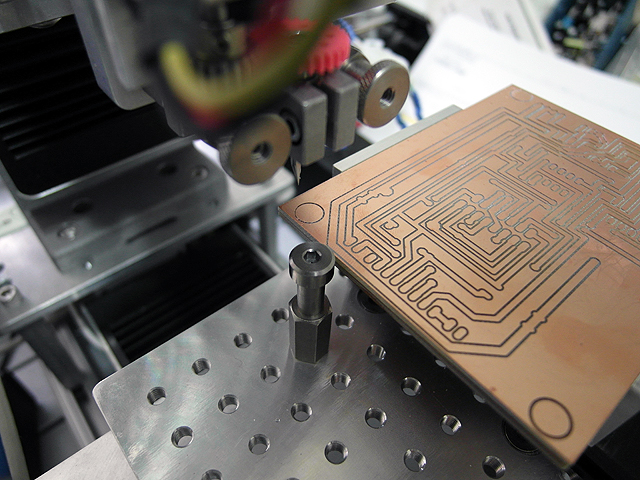

PCB milling vise (2/19/2012) Modified taig 1225-T vise with new jaws designed to hold a 4" PCB. |

|

PCB milling vise (2/19/2012) Modified taig 1225-T vise with new jaws designed to hold a 4" PCB. |

|

PCB milling vise (2/19/2012) Modified taig 1225-T vise with new jaws designed to hold a 4" PCB. |

|

PCB milling vise (2/19/2012) Modified taig 1225-T vise with new jaws designed to hold a 4" PCB. |

|

|

PCB milling vise (4/9/2012) PCB board stop for reproducible board positioning. |

|

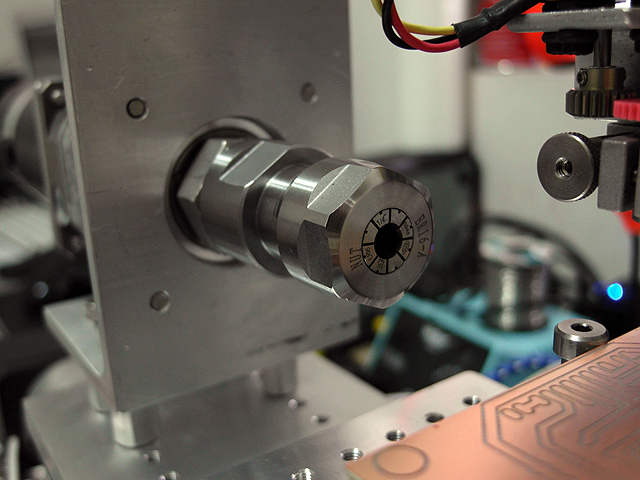

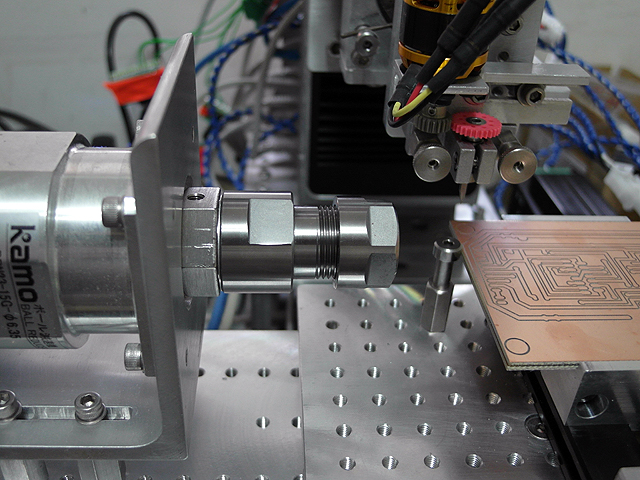

ER16 collet adapter (4/9/2012) Mounts on A axis, provides accurate work holding. |

|

ER16 collet adapter (4/9/2012) Mounts on A axis, provides accurate work holding. |

|

ER16 collet adapter (4/9/2012) Mounts on A axis, provides accurate work holding. |

|

|

|

|

|

|

By attempting to reproduce any experiments or devices listed on this domain in part or in whole, you agree to hold me harmless against any lawsuit or liability. Copyright © 1998 - 2013 by Andrew Seltzman. All rights reserved. |

|

| Contact me at: admin@rtftechnologies.org | |