| Overview:

This research was conducted in four phases:

- 1998-1999 : Development of Lithium cell design and testing varied

cathode metal-salts. Electrolyte selected.

- 2000-2001 : Testing various concentrations of electrolyte on current

output over 400s interval.

- 2001-2002 : Testing of various anions in lithium cells.

- 2002-2003 : Development of ion gradient theory, expanded data logging

and more controlled environment allows automated logging for 3600seconds

and multiple trials. Research in water concentration affecting gradient

formation and tabulations of peak and steady state current. Research

presented at Intel ISEF.

Read the paper here

, or on the web below. |

| |

| Abstract

The requirement of an anhydrous and aprotic electrolyte in lithium cells

prevents the use of aqueous electrolytes with unity transference. The

use of non-unity transference electrolytes causes concentration gradients

to form reducing the current output of the cell by increasing electrolyte

resistance.

These experiments were designed to analyze the performance of primary

lithium cells when the radii of the anion, the concentration of the electrolyte,

and the amount of water contamination in the electrolyte were varied.

This effects the rate of gradient formation and the magnitude of the gradient

at steady-state current.

It was concluded that water plays a role in increasing the rate of gradient

formation of ions with smaller radii. Furthermore, it was concluded that

a high electrolyte concentration increases the formation rate of gradients

by decreasing ion mobility due to a high viscosity.

|

| |

| Introduction Lithium

cells are becoming an increasingly important part of portable power sources

due to their high energy density and low weight. To fulfill their full

potential, lithium cells must overcome several limitations. The most significant

of these limitations is the formation of ion gradients in the cell’s

electrolyte. Such gradients impede the amount of current that the cell

can produce. Overcoming this limitation will allow lithium cells to output

an increased amount of current.

Based on earlier studies that have been conducted on lithium / silver

salt cells, it was observed that current output depended on electrolyte

concentration, viscosity, and the particular anion of the silver salt.

From reading and consultation, I have come to focus subsequent studies

on the effect of these variables on the formation of ion gradients in

these cells as an underlying factor effecting the current output.

|

| |

| Hypothesis Therefore

it is hypothesized that Li | Ag-salt cells utilizing silver salts with

anions of increasing radii will form ion gradients of different magnitudes.

These gradients will be observable as the peak in current output. It is

further hypothesized that Li | Ag-salt cells will have decreasing ion

transference rates in a LiBF4 electrolyte of increasing concentration

when the anion is not varied. This will lead to the formation of ion gradients

of increasing magnitude. The experiments described in this report were

intended to test the above stated hypotheses. Furthermore, the results

of the presented research will determine the optimum ion radii and electrolyte

concentration for lithium cells in order to optimize output current.

|

| |

| Background Concentration

Gradient formation has been a known problem in lithium cells. Concentration

gradients form when the rate of ion generation is not matched in rate

by ion transfer across the cell. Ion diffusion is driven by entropy, as

the ions try to become evenly distributed across the cell. Initially,

when current begins to flow through a cell, there are no ion gradients

present, the electrolyte resistance is at a minimum, and therefore the

cell is producing the maximum amount of current possible; this is called

initial current (I0). During current generation, an ion gradient forms

in a lithium cell since the rate of ion transport away from the anode

and cathode of the cell is less than the rate at which the ions accumulate

at the originating electrode.

Once ion gradients form, ion transport becomes limited and the resistance

of the electrolyte increases. This increase in electrolyte resistance

is due to concentration polarization of the electrolyte is defined as

a build up of anion/cation in a cell’s electrolyte. Concentration

polarization reduces the output current by introducing a counter EMF in

the electrolyte of a cell, therefore increasing the cell’s internal

resistance to the flow of current. This reduces the output current until

the rate of ion generation is equivalent to the rate of ion transport.

When this equilibrium point is reached, the current output remains constant;

this is called steady state current.

An ion’s radius has an effect on gradient formation in Li cells.

Therefore, ion radii calculated using the Kapustinskii equation [1] were

compared to current output. As anionic radii increase, the volume of an

anion increases, therefore distributing the anionic charge over a greater

volume. This decrease in the anion’s charge density has an effect

on intermolecular forces between an anion and water contamination in the

electrolyte.

The current output of a lithium cell is also dependent on the electrolyte

used. Since "lithium is more electropositive than hydrogen, the electrolyte

must be nonaqueous and aprotic" [2]. This requirement prevents the

use of aqueous electrolytes with unity transference in lithium cells.

The use of non-unity transference electrolytes causes formation of concentration

gradients, reducing the current output of the cell by increasing electrolyte

resistance. Experiments described in this report were designed to analyze

the performance of primary lithium cells when the concentration of the

electrolyte used in the cell was varied for a given silver salt. It was

postulated that this would effect the rate of gradient formation, the

magnitude of the gradient, and current output when steady-state current

is achieved.

Together, the studies described here were carried out to determine the

effects that anion size, and the corresponding anionic charge density,

and electrolyte concentrations have on gradient formation and current

output in Li cells.

|

| |

| Materials

1tank Argon

1 Dryrite tube

1 Lab. Con. Co. 50004 glove box

1sheet Bounty two-ply Paper towels

1 Wire cutter

1 razorblade

45 1ml plastic Tuberculin syringes

1 Craftsman 82325 PC interface multimeter

1 Glue gun

4 Hot melt glue sticks

35cm 3.4 mm Lithium wire (1% Sodium)

100ml C4H10O2 1,2-Dimethoxy ethane, CAS: 110-71-4, 99.5% Anhydrous

100ml C4H6O3 Propylene carbonate, CAS: 108-32-7, 99.7% Anhydrous

10g LiBF4 Lithium tetrafluoroborate, CAS: 14283-07-9, 98% Anhydrous

5g AgF Silver Fluoride, CAS: 7775-41-9

5g AgCN Silver Cyanide, CAS: 506-64-9

5g AgI Silver Iodide, CAS: 7783-96-2

5g AgBr Silver Bromide, CAS: 7785-23-1

5g AgNO3 Silver Nitrate, CAS: 7761-88-8

5g AgClO4 Silver Perchlorate, CAS: 7783-93-9

1sheet 160# sandpaper

10ml Hexane

6 20 ml scintillation vials

6 1dram vials

6 6cmX6cm-aluminum foil squares

1 25 ml volumetric flask

2 18" 16 gauge non-coring needle

4m 18 AWG bare copper wire

1 Tweezers

|

| |

Methods

Note: All experiments were done in a Lab. Con. Co. 50004 glove box under

Argon to provide an anhydrous environment. All stock chemicals were 98%

anhydrous or better. Atmosphere was dried with P2O5.

1. Preparation of chemicals

1a. Prepare a 0.0 g/ml stock solution of [electrolyte LiBF4] in 1,2-Dimethoxyethane

and Propylene carbonate; 1:1 by volume. .

1b. Prepare stock solution of 0.4 g/ml LiBF4 in 1,2-Dimethoxyethane: Propylene

carbonate, 1:1 by volume, of electrolyte

1c. Similarly, prepare the following electrolyte concentrations: 0.0 g/ml,

0.1 g/ml, 0.2 g/ml, 0.3 g/ml, and 0.4 g/ml .

1d. Grind each of the 6 silver salts listed in the “Materials”

section to a fine powder (150 mesh) and add them to separate 1dram vials

wrapped in aluminum foil.

2. Construction of cells

2a. Cut 1cm long pieces of the 3.4 mm lithium wire into a scintillation

vial filled with hexane.

2b. Remove the plungers from 1 ml Tuberculin syringes and cut the barrels

at the 0.6ml mark with a razorblade.

2c. Sand the 18 AWG un-insulated copper wire using grade 160# sandpaper.

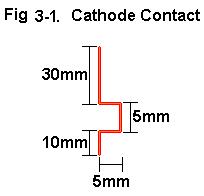

2d. Cut 55 mm pieces from the copper wire and construct cathode contacts

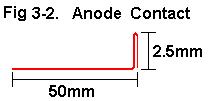

per Fig 3-1.

2e. Construct anode contacts per Fig 3-2.

2f. Insert the anode contact, long end first, through the syringe barrel

into the tip end of the syringe so that the straight piece of wire extends

through the end of the syringe and the loop end is in the inside of the

syringe barrel. Push the copper wire in until the loop reaches the bottom.

Connect the barrel to a vacuum source and draw hot melt glue into the

tip until it reaches the bottom of the loop.

2g. To construct separators, cut 3 cm X 2 cm rectangular pieces out of

the Bounty paper towel. Fold them into thirds along the 3 cm direction

and then roll the folded towel into a cylinder. Insert 10 separators into

a syringe barrel from which the tip was cut off. This will allow the separators

to be pushed out into the cells one at a time.

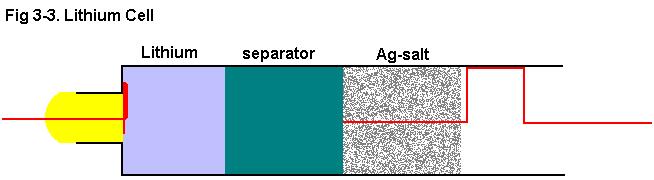

2h. Assemble lithium cells per Fig 3-3.

Note: Cells were tested in a vertical position with the cathode up.

Testing Li-cell properties

The lithium cells were assembled per Fig 3-3. Cells were tested in a vertical

position with the cathode up.

(1) Effect of electrolyte concentration on current output

1a. Insert a cleaned 1 cm piece of lithium into the syringe barrel and

compact the wire so it forms a tight seal at the edges of the syringe

and is in electrical contact with the copper anode contact.

1b. Add 0.3 ml of a variable concentration electrolyte, (0.0 g/ml, 0.1

g/ml, 0.2 g/ml, 0.3 g/ml, or 0.4 g/ml).

1c. Inject one separator into the lithium cell. Subject cell to light

vacuum to remove argon bubbles from separator.

1d. Start timer and add 0.2 ml of AgNO3.

1e. After 90 sec insert the cathode contact and connect multimeter.

1f. After 130 sec start data logging. Logging program will record current

output of the cell every second over a duration of 400 seconds.

1g. Repeat for electrolyte concentrations 0.0 g/ml through 0.4 g/ml

(2) Effect of electrolyte concentration on electrolyte conductivity

2a. Add 0.4 ml of variable concentration electrolyte (0.0 g/ml, 0.1 g/ml,

0.2 g/ml, 0.3 g/ml, or 0.4 g/ml) into a syringe barrel.

2b. Insert the cathode contact 1cm from anode contact and connect multimeter.

2c. Start data logging. Logging program will record resistance of the

cell every second for a duration of 400 seconds.

2d. Repeat for electrolyte concentrations 0.0 g/ml through 0.4 g/ml.

(3) Effect of electrolyte concentration on electrolyte viscosity.

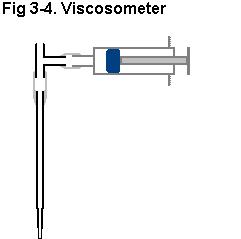

3a. Measure electrolyte fall time through a 1 ml TD pipette from the 0.9

ml mark to the 0.0 ml mark (viscosometer, Fig 3-4) for electrolytes (0.0

g/ml, 0.1 g/ml, 0.2 g/ml, 0.3 g/ml, or 0.4 g/ml).

3b Calibrate viscosometer by measuring the fall time of water from the

0.9 ml mark to the 0.0 ml mark.

(4) Effect of ion radius on gradient formation and steady state

current

4a. Insert a cleaned 1 cm piece of lithium into the syringe barrel and

compact the wire so it forms a tight seal at the edges of the syringe

and is in electrical contact with the copper anode contact.

4b. Add 0.3 ml of the 0.2 g/ml electrolyte solution.

4c. Inject one separator into the lithium cell. Subject cell to light

vacuum to remove argon bubbles from separator.

4d. Start timer and add 0.2 ml of cathode salt. (AgF, AgCN, AgBr, AgNO3,

AgI, or AgClO4)

4e. After 90 sec insert the cathode contact and connect multimeter.

4f. After 130 sec start data logging. Logging program will record current

output of the cell every 4 seconds over a duration of 3600 seconds.

4g. Repeat 4 times with each cathode salt.

(5) Effect of water concentration on gradient formation.

5a. Insert a cleaned 1 cm piece of lithium into the syringe barrel and

compact the wire so it forms a tight seal at the edges of the syringe

and is in electrical contact with the copper anode contact.

5b. Add 0.3 ml of the 0.2 g/ml electrolyte solution with variable water

content (0.2%, 0.1%, or 0.01%).

5c. Inject one separator into the lithium cell. Subject cell to light

vacuum to remove argon bubbles from separator.

5d. Start timer and add 0.2 ml AgNO3

5e. After 90 sec insert the cathode contact and connect multimeter.

5f. After 130 sec start data logging. Logging program will record current

output of the cell every 5 seconds over a duration of 3600 seconds.

5g. Repeat 4 times with each electrolyte of variable water concentration.

|

| |

| Data: see archive

http://www.rtftechnologies.org/Design/Assets/files/licell/ |

| |

Results

•

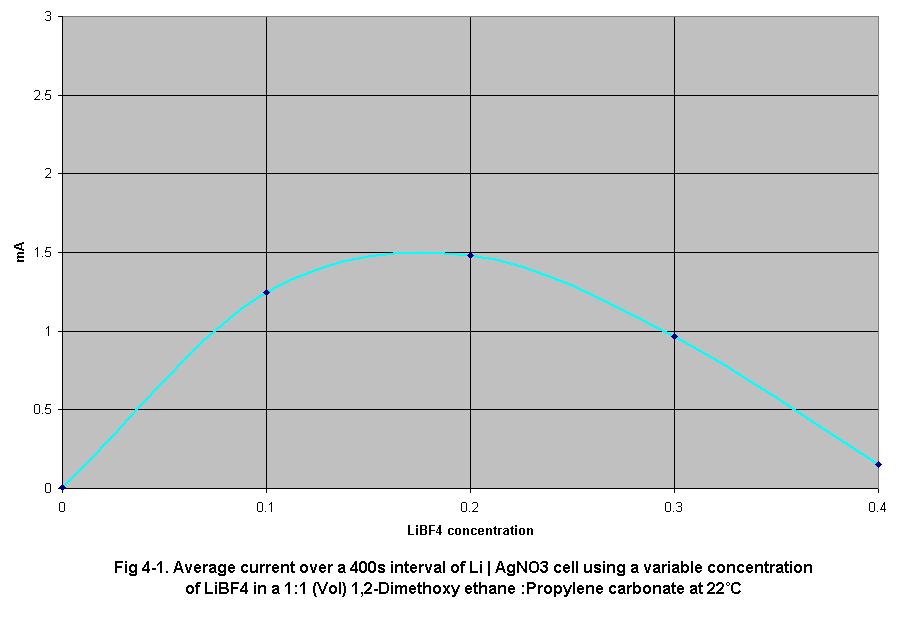

Fig 4-1 shows the average output current of a Li/AgNO3 cell as electrolyte

concentration is increased. Output current increases up to a point as

electrical resistance decreases, however it begins to decrease as the

electrolyte viscosity begins to impede ion travel resulting in concentration

polarization of the electrolyte.

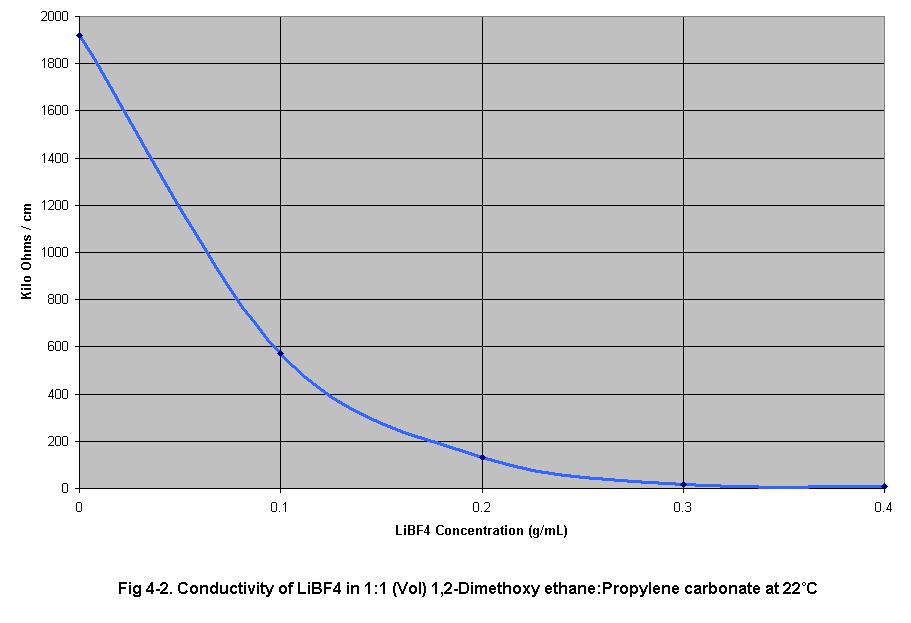

• Fig

4-2 shows an increase in electrolyte conductivity as the electrolyte

concentration increases.

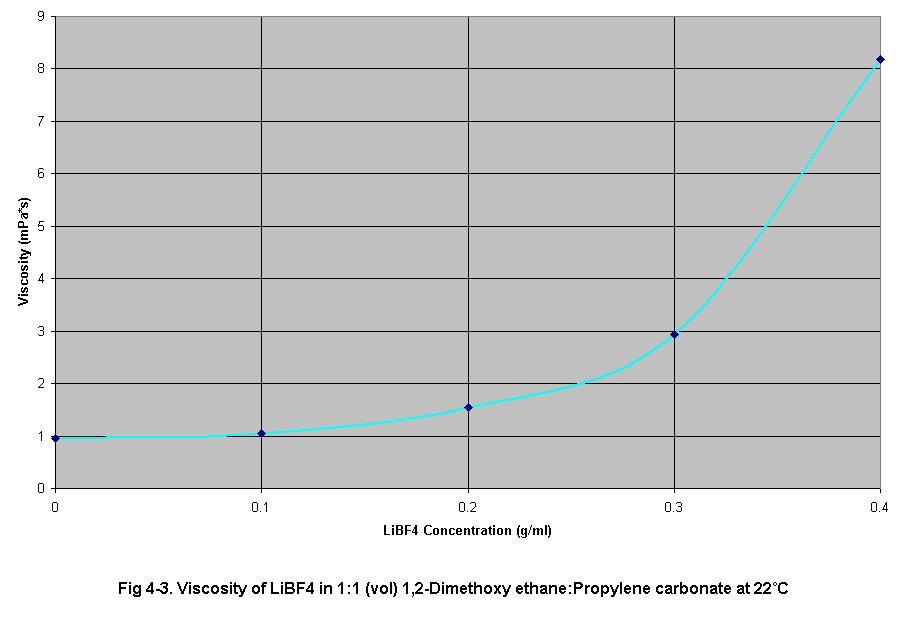

• Fig 4-3

shows an increase in electrolyte viscosity as electrolyte concentration

increases. This increase in viscosity impedes ion travel increasing the

internal resistance of the cell.

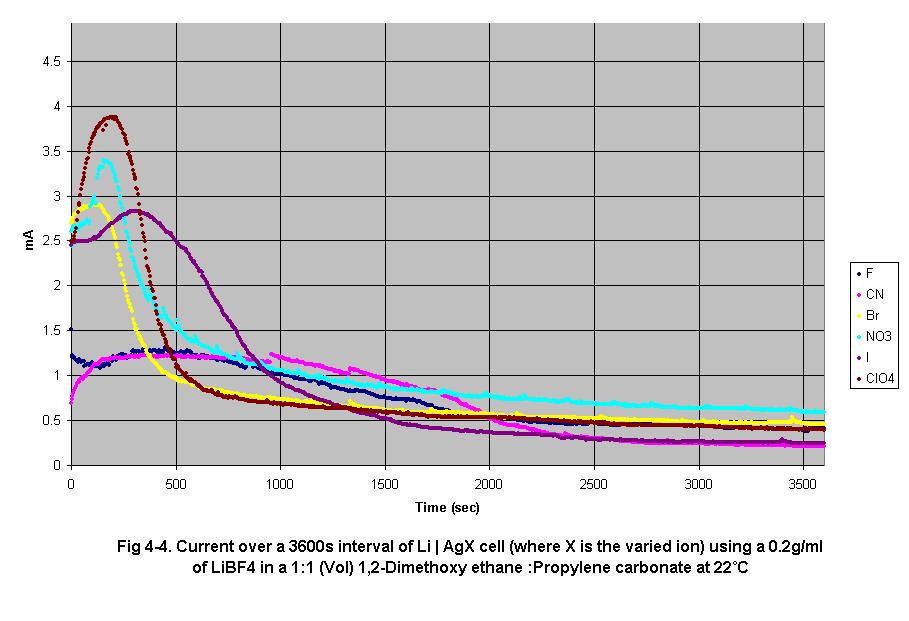

• Fig 4-4

shows an increase in peak output current as anion radius increases. This

increase in current reflects the mobility of the anion in the cell’s

electrolyte. All anions used in this experiment have a –1 charge,

only their radii change. As an anion’s radii increases, it’s

volume increases as well, decreasing its charge density. Since water has

a dipole moment, it is attracted to a given anion with a force directly

proportional to the anion’s charge density. Smaller anions have

a greater charge density and attract more water molecules increasing its

effective volume and therefore decreasing it’s diffusion rate.

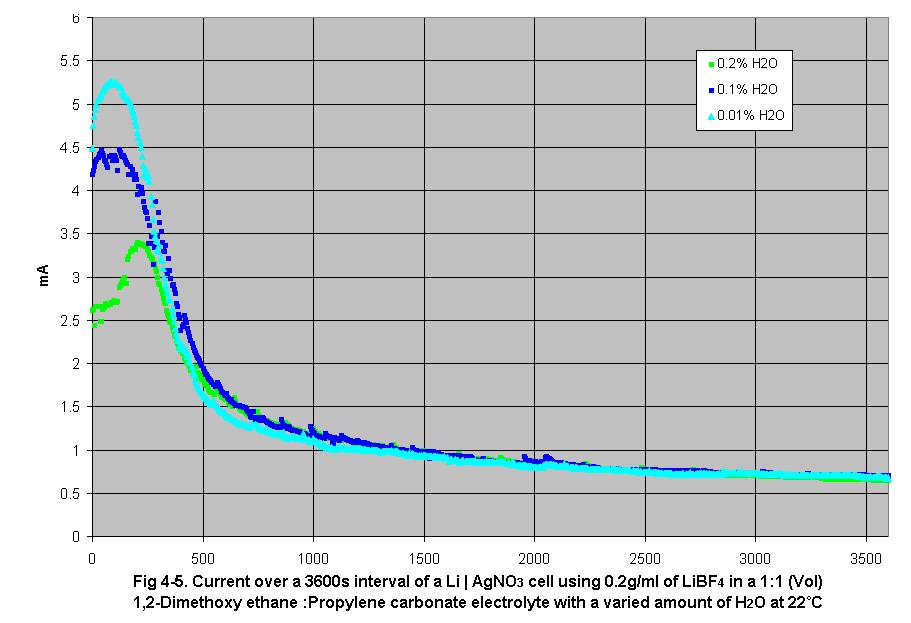

• Fig

4-5 shows that as water contamination in the electrolyte increases,

peak current output current decreases. This effect is due to the water’s

attraction to the anion, increasing the effective volume. This effective

increase in the anion’s volume reduces its diffusion rate, increasing

the magnitude of concentration polarization in the electrolyte.

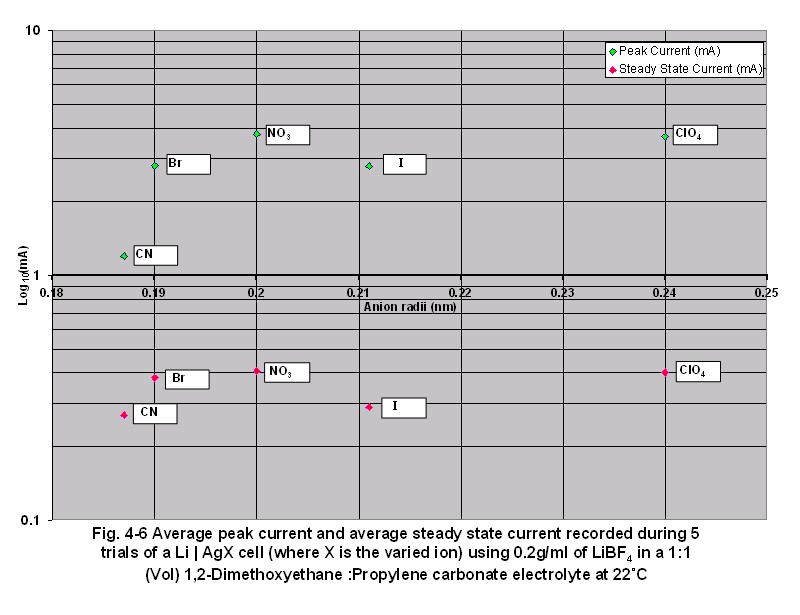

• Fig

4-6 shows the averages of the peak currents and steady state currents

recorded during 5 trials for each anion. As anion radii increased, both

the averages of peak and steady state current increased due to the lower

magnitude of ion gradients of the larger anions.

|

| |

| Discussion

In this research project five sets of experiments were conducted to analyze

ion gradient formation in Li/Ag-salt cells. These were:

1. Effect of electrolyte concentration on current output;

2. Effect of electrolyte concentration on electrolyte viscosity;

3. Effect of electrolyte concentration on electrolyte conductivity.

4. Effect of ion radius on ion gradient formation and steady state current.

5. Effect of water on ion gradient formation and steady state current

1. Effect of electrolyte concentration on current output

The results of set (1) experiments show average current output over a

400 sec duration as electrolyte concentration increased from 0.0 g/ml

to 0.4 g/ml in 0.1 g/ml increments. As electrolyte concentration increased,

current of Li-AgNO3 cells, used as standards, increased from 0.012 mA

at 0.0 g/ml to a peak of 1.585 mA at 0.2 g/ml and then decreased to 0.15

mA at 0.4 g/ml. This peak occurred at 0.2 g/ml due to optimum ion transference

rates at this concentration. The decrease in average current at electrolyte

concentrations greater then 0.2 g/ml is caused by the increased rate of

concentration gradient formation in the electrolyte caused by decreasing

transference rates due to the increase in electrolyte viscosity, (Fig

4-3). The increasing viscosity of the electrolyte decreased ion mobility

and the rate of ion diffusion of the cell causing areas of higher ion

density localized at the surfaces of the anode and cathode.

2. and 3. Effect of electrolyte concentration on electrolyte viscosity

and electrolyte conductivity

The results of set (2) and set (3) experiments show electrolyte viscosity

and electrolyte conductivity, respectively, as electrolyte concentration

increased from 0.0 g/ml to 0.4 g/ml in 0.1 g/ml increments. As electrolyte

concentration increased, conductivity and viscosity increased in an exponential

manner. In the lithium cells tested, (Fig 4-1), the effect caused by the

increase in conductivity was canceled out by the increase in viscosity

at 0.2 g/ml in regards to the average current output over a 400 sec interval.

This is due to higher viscosity electrolytes yielding lower rates of ion

diffusion. This causes an increase in the formation rate of concentration

gradients. These gradients reduce the current output of the cell.

4. Effect of ion radius on ion gradient formation and steady-state current

In this set of experiments, the rate of gradient formation increased as

ion radius increased. Since the electrolytes used were only 99.8% anhydrous,

as tested on a Karl-Fisher titratior, the relatively large amount of water

in the electrolyte impeded the motion of small ions, causing the formation

of gradients of a high magnitude near the cathode resulting in lower initial

current.

| Fig 5-1. Anion radius |

|

|

|

|

|

|

| Anion |

F |

CN |

Br |

NO3 |

I |

ClO4 |

| Anion radius (nm) |

0.126 |

0.187 |

0.19 |

0.2 |

0.211 |

0.24 |

As ion radius decreased (Fig 5-1), charge density of the ion increased

since the anionic charge was localized in a smaller volume. Since water

has a dipole moment, it is attracted to the anions with a force proportional

to the charge density. Smaller ions with higher charge density attract

more water molecules increasing the effective volume of the ion and therefore

have lower transference rates than larger ions with lower charge densities.

This effect can be seen in the results illustrated in Fig 4-4. As ion

radius increased, most cells show a higher peak current and a faster decrease

in current until current approached a steady state. At this point the

cell reached equilibrium, when the ion diffusion rate became equal to

the rate of ion production.

The peak current was caused by the increase in dissolved cathode salt

as the cell was run. The dissolved cathode salts would be in contact with

the cathode electrode, therefore increasing the effective surface area

possible to accept electrons from. This increases the current output until

ion gradients of an effective magnitude form, therefore limiting current.

The formation rate of these gradients would depend on the amount of water

in the electrolyte as well as the current flowing through the cell.

It should also be noted that as the cell runs, the electrolyte slightly

increases in concentration. Although the results in Fig 4-1 suggest that

peak current occurred at 0.2 g/ml LiBF4 in a solution 1:1 by volume of

1,2-dimethoxyethane and propylene carbonate, it should be noted that the

current was determined at electrolytes between 0.0 g/ml and 0.4 g/ml in

0.1 g/ml steps. It is known from the data in Fig 4-2 that when electrolyte

concentration increased, conductivity increased as well. Therefore it

is reasonable to assume that the conductivity of a given electrolyte will

increase as the cell is run, increasing current output, before ion gradients

cause a noticeable increase in electrolyte resistance and the cell starts

to approach steady-state current.

5. Effect of water on ion gradient formation and steady-state current

In this set of experiments, the gradient formation increased as the water

in the electrolyte increased as seen in fig 4-5. It was observed that

as water concentration increased, peak current decreased. The increase

in water concentration causes ion gradients to increase demonstrating

that water contamination in the electrolyte will reduce output current

due to the attraction between anion and water.

|

| |

|

|

| |

| Conclusion In

these experiments lithium cells were constructed to test the following

hypotheses:

• The ion migration rates in Li | Ag-salt cells will increase as

anion radii increases.

• Li | Ag-salt cells with a given anion will have decreasing ion

transference rates in a LiBF4 electrolyte of increasing concentration.

Increasing the LiBF4 concentration in the electrolyte of a Li|AgNO3 cell

increases the formation rate of gradients. This causes a resistance increase

in the electrolyte and therefore a decrease in current output. The increasing

viscosity of the electrolyte decreased ion mobility and the rate of ion

diffusion in the cell causing areas of high ion concentration localized

at the surfaces of the anode and cathode.

Ions with small radii showed a high initial rate of gradient formation.

This effect is due to the water in the electrolyte impeding the motion

of small ions, causing the formation of gradients of a high magnitude

near the cathode. The presence of these gradients resulted in a lower

initial current (Io) delaying peak output due to the slow rate at which

ion pairs were produced. Ions with larger radii show a higher current

peak due to the higher initial transference rate.

Further research of these properties in variably hydrated electrolytes

have shown that an increase in water in the electrolyte causes the current

output to decrease since the water is attracted to the anion. This increase

in the anion’s effective volume causes a decrease in ion transport

away from the cathode, increasing the rate at which ion gradients form.

The results of this research showed that water contamination decreases

the current output of cells utilizing ions with smaller radii and that

electrolyte concentration in addition to ion radii effects the magnitude

of ion gradients in the electrolyte. The optimum Li|Ag-salt cell would

have a 0.2 g LiBF4 / ml electrolyte, an anion with the maximum practical

radii and a minimum amount of water in the electrolyte.

|

| |

| Acknowledgements

This research was conducted during the months July-October 2002. Laboratory

space was provided by RTI International.

Supplies and assistance were provided by Herbert Seltzman. Professor Peter

S Fedkiw and Ruchi Singhal of the Chemical Engineering Department, NCSU,

provided background information on gradient formation in lithium cells

as well as guidance on formatting a research paper.

|

| |

| References: [1]

Bruce, Peter G., James Evans, and Colin A. Vincent. (1988). Conductivity

and Transference Number Measurements on Polymer Electrolytes. Solid State

Ionics: 918-922.

[2] Jenkins, Donald B., Jack Passmore, Leslie Glasser, and Helen K.

Roobottom et al (1999). Thermochemical Radii of Complex Ions. Journal

of Chemical Education. N.p.: The Division of Chemical Education of the

American Chemical Society, 1570-1573.

[3] Mayes, Anne M., and Donald R. Sadoway. (2002). Portable Power: Advanced

Rechargeable Lithium Batteries. MRS Bulletin: 590-592. 3 September 2002.

<http://www.mrs.org/publications/bulletin>.

[4] Linden, David. Handbook of Batteries. (1995).2nd ed. Washington,

D.C.:

McGraw-Hill, INC, 2.15-2.18.

[5] Crompton, TR. (1995). Battery Reference Book. . N.p.: Butterworth-Heinemann

Ltd,

[6] Handbook of Chemistry and Physics. (1976) . N.p.: CRC Press.

Handbook of Chemistry and Physics. (1959). N.p.: Chemical Rubber Co.

[7] Heise, George W. (1971). The Primary Battery. 1st. Ed. N.p.: John

Wiley and Sons P.

[8] "Lithium." (1993). Compton's Interactive Encyclopedia. N.p.:

Compton's NewMedia, Inc. N.

[9] Fedkiw, Peter S., (April - November 2002). Personal communications.

Department of Chemical Engineering, NCSU, Raleigh, NC.

|