| Orbital TIG Welding System |  |

|

|

|

|

|

|

|

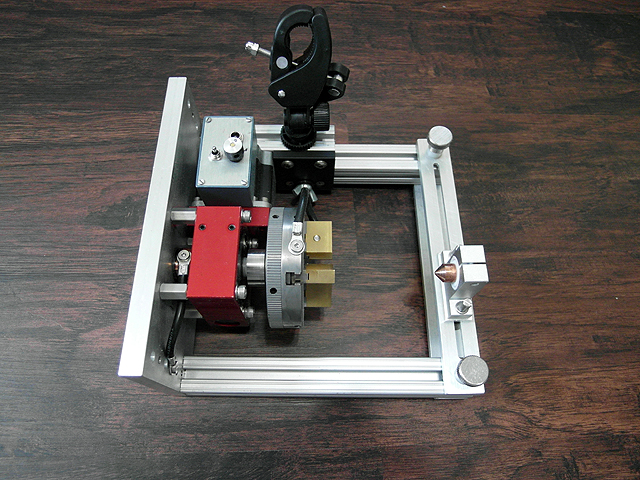

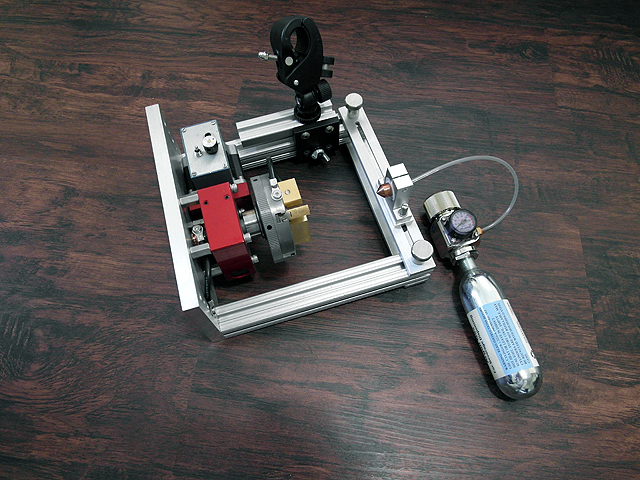

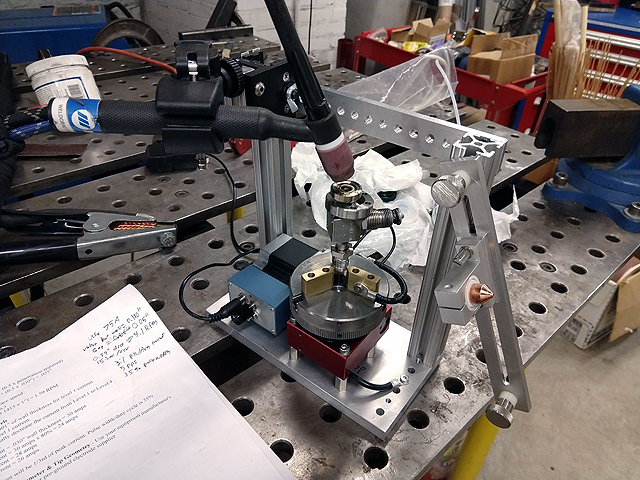

| A system allowing orbital TIG welding of small tube components and swagelok valves. Orbital TIG welding system holds TIG torch and rotates weld components. |

|

|

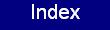

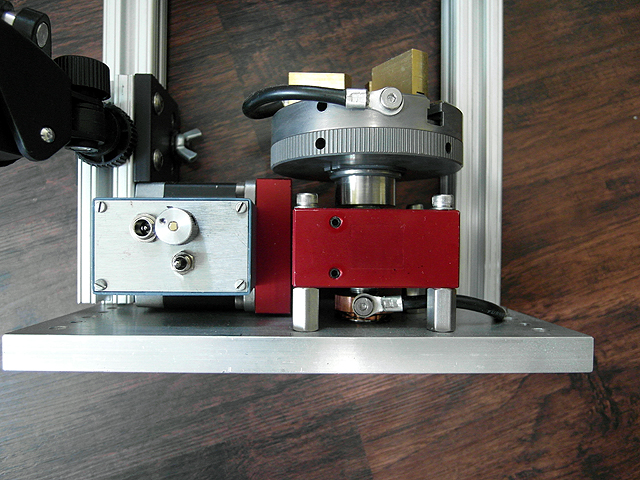

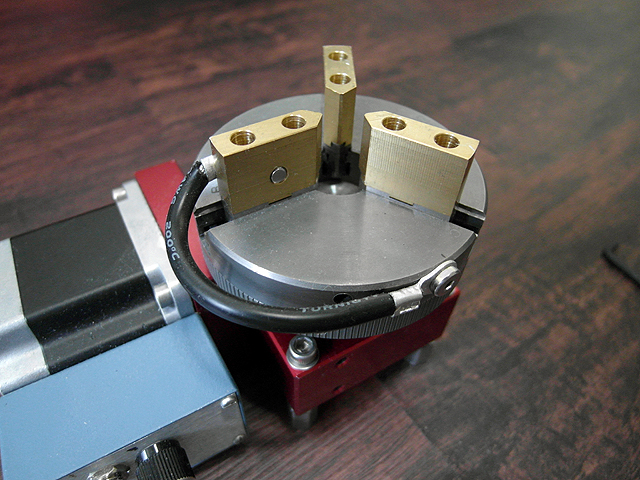

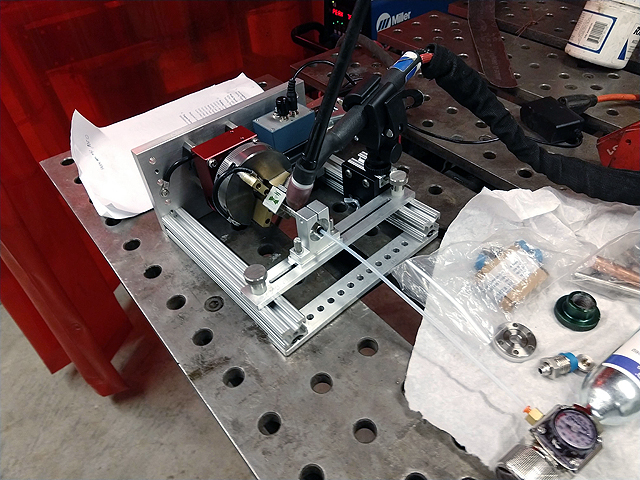

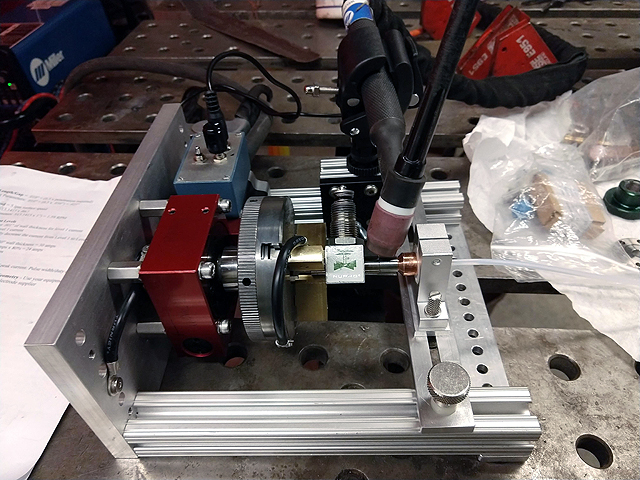

Orbital TIG Welding System (9/3/2018) Valve body and tube adapter held in chuck. TIG torch held over weld area. |

|

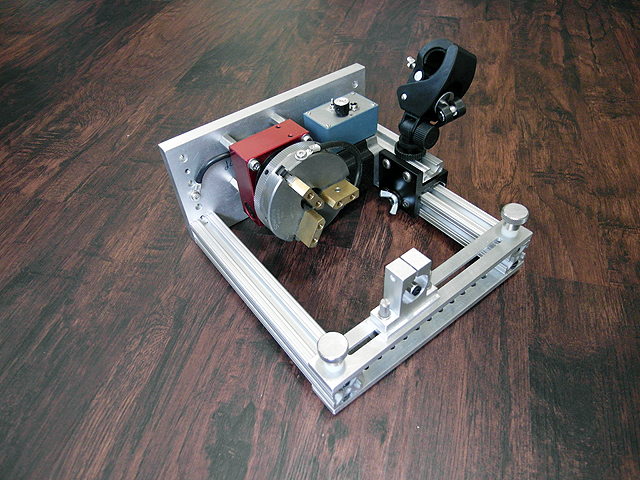

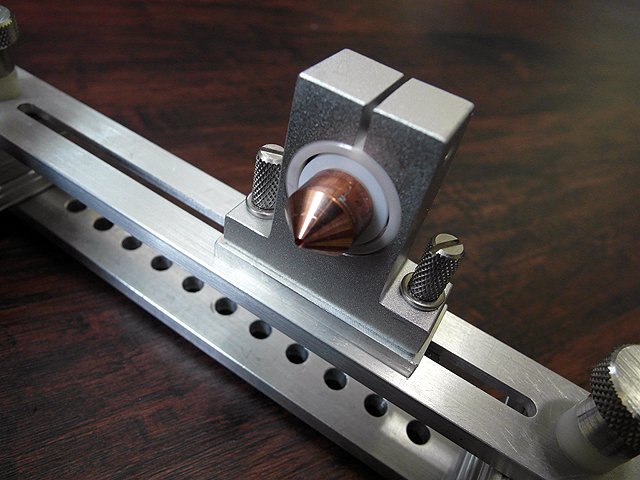

Orbital TIG Welding System (9/3/2018) Torch holder is mounted on a sliding linear bearing for easy positioning. Frame is made out of 8020 extruded aluminum. |

|

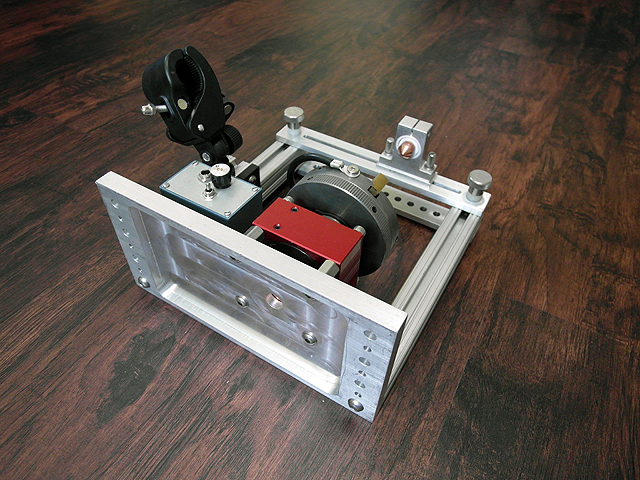

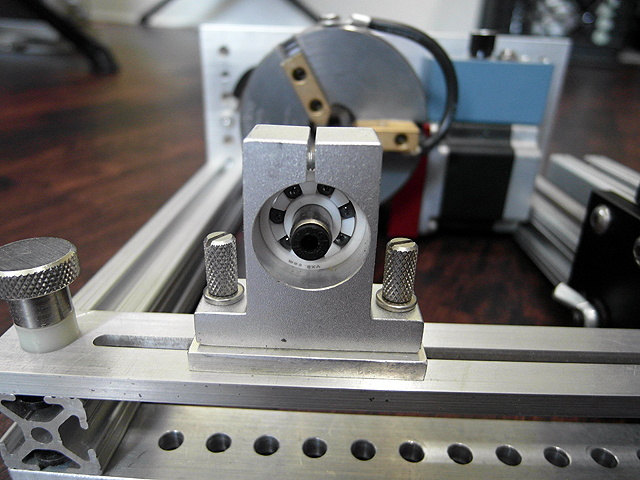

Orbital TIG Welding System (9/3/2018) Tailstock has a gas feed to purge the interior of the tube with Argon. |

|

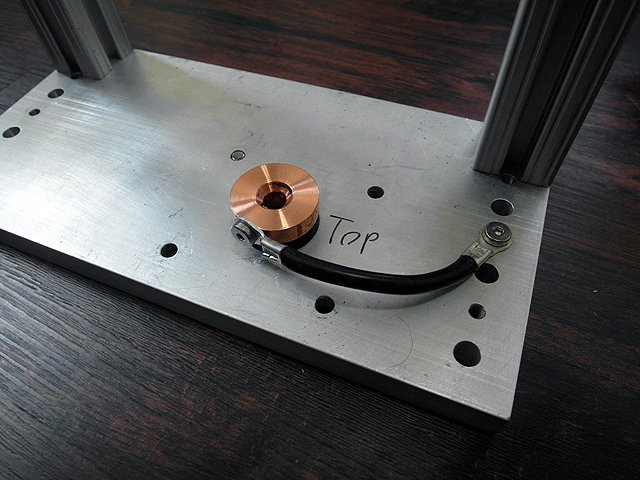

Orbital TIG Welding System (9/3/2018) Mounting plate machined out of aluminum holds gearbox and frame. |

|

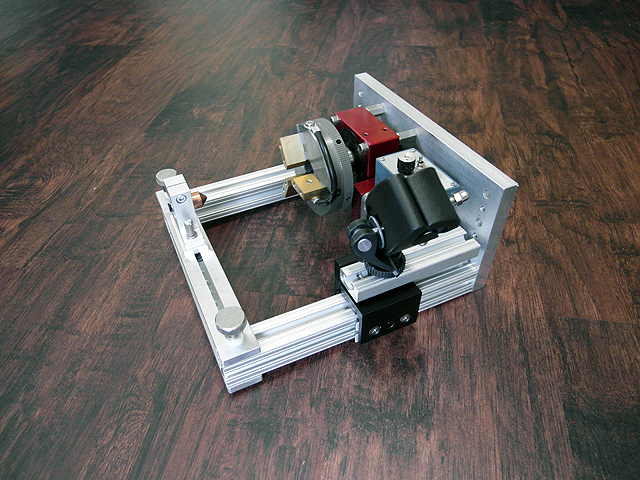

Orbital TIG Welding System (9/3/2018) Torch holder is a Bicycle handlebar mount for a Gopro Hero (after market). |

|

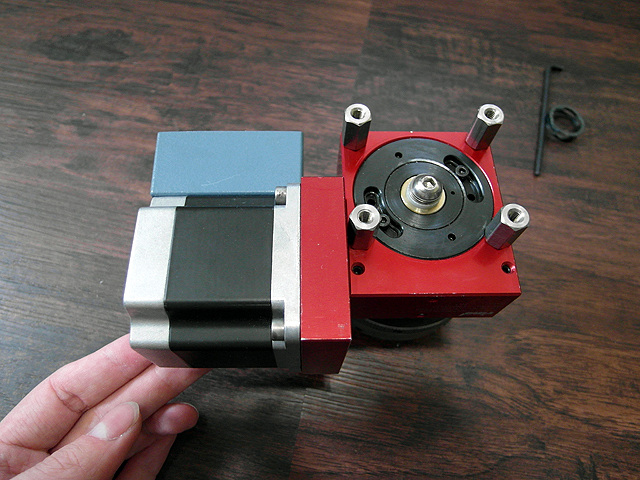

Orbital TIG Welding System (9/3/2018) Gearbox mounts to aluminum base plate. VEXTA STEPPER MOTOR: |

|

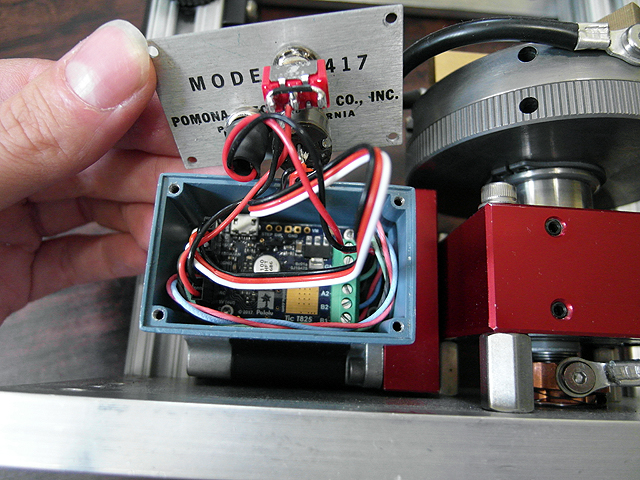

Orbital TIG Welding System (9/3/2018) The stepper controller is a Pololu TIC T825 |

|

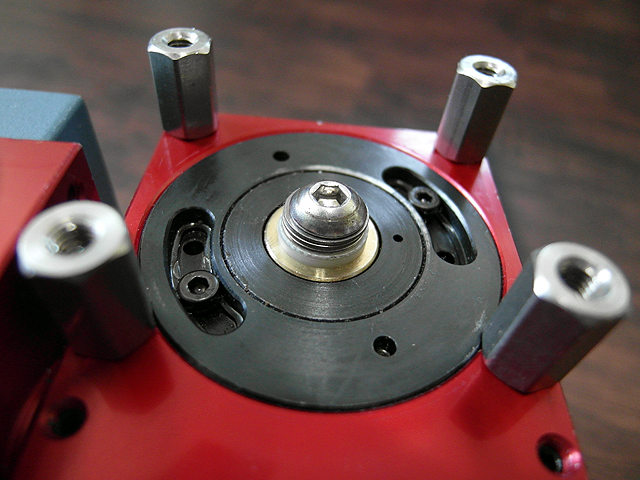

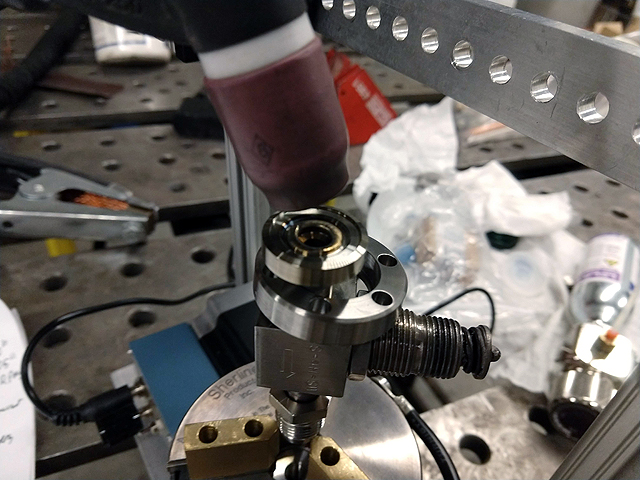

Orbital TIG Welding System (9/3/2018) The current flows down the drawbar (a 1/4-20 bolt) which is insulated from the gearbox so current doesn't flow through the worm gear or bearings. |

|

Orbital TIG Welding System (9/3/2018) The current flows down the drawbar (a 1/4-20 bolt) which is insulated from the gearbox so current doesn't flow through the worm gear or bearings. |

|

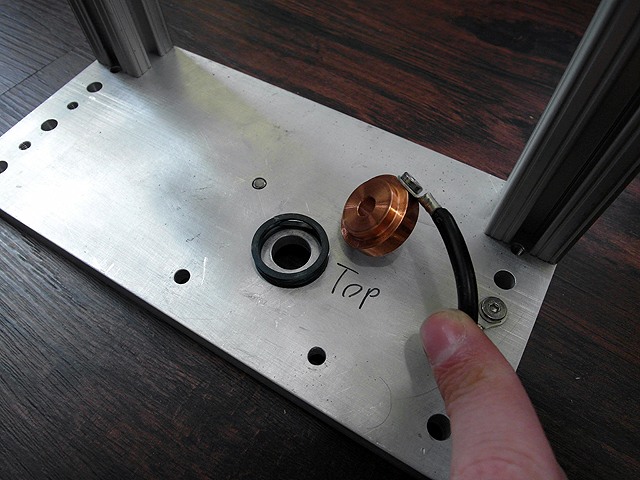

Orbital TIG Welding System (9/3/2018) The current is grounded by a spring loaded copper brush that is presses against the back of the drawbar. |

|

Orbital TIG Welding System (9/3/2018) The current is grounded by a spring loaded copper brush that is presses against the back of the drawbar. |

|

Orbital TIG Welding System (9/3/2018) The chuck is capable of continuous rotation, the wire on the jaw connects to the chuck body so weld current dosen't flow through the jaw ways or scroll. |

|

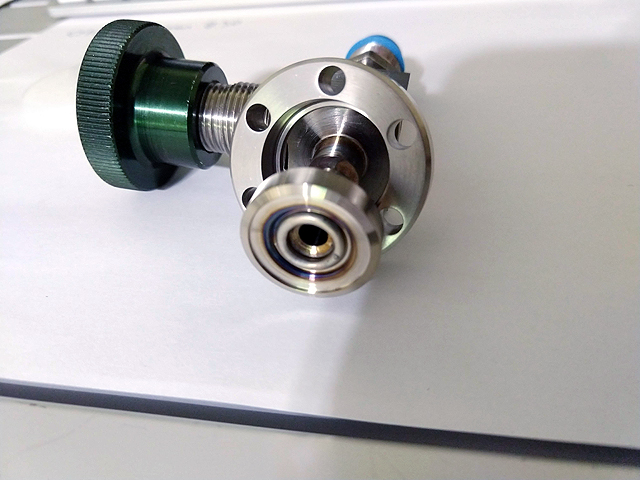

Orbital TIG Welding System (9/3/2018) Tailstock has a gas feed to purge the interior of the tube with Argon. |

|

Orbital TIG Welding System (9/3/2018) Tailstock has a gas feed to purge the interior of the tube with Argon. |

|

Orbital TIG Welding System (9/3/2018)

|

|

Orbital TIG Welding System (9/3/2018)

|

|

Orbital TIG Welding System (9/3/2018)

|

|

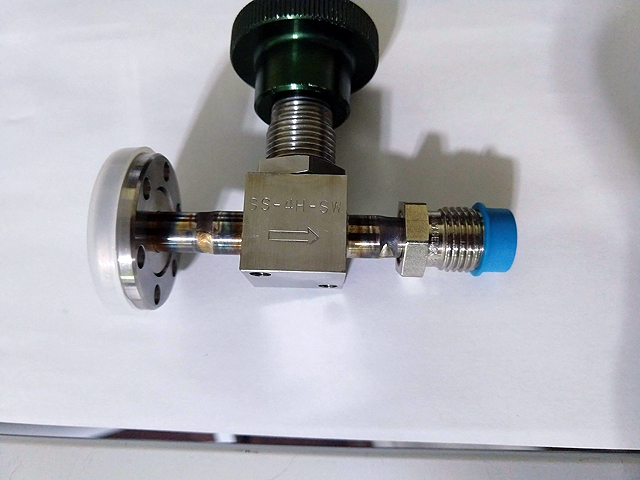

Orbital TIG Welding System (9/3/2018) Torch can be positioned vertically for welding conflat flanges |

|

Orbital TIG Welding System (9/3/2018) Torch can be positioned vertically for welding conflat flanges |

Orbital TIG Welding System (9/3/2018) Testing clearance from valve body |

|

|

Orbital TIG Welding System (9/3/2018) Welded valve assembly |

|

Orbital TIG Welding System (9/3/2018) Welded valve assembly Calculations used for the but weld onto the valve were adapted from: |

Orbital TIG Welding System (9/3/2018)

|

|

By attempting to reproduce any experiments or devices listed on this domain in part or in whole, you agree to hold me harmless against any lawsuit or liability. Copyright © 1998 - 2018 by Andrew Seltzman. All rights reserved. |

|

| Contact me at: admin@rtftechnologies.org | |